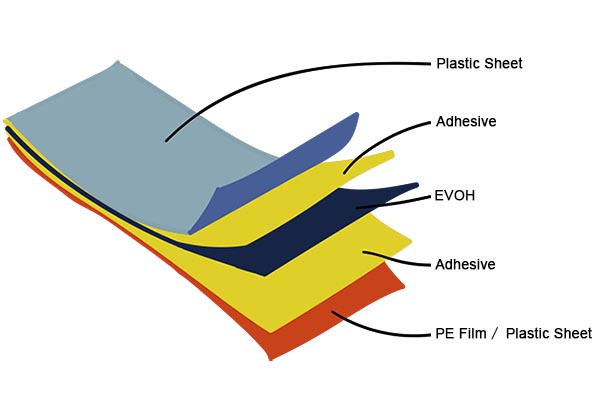

Pele ho tsohle, themultilayer co-extrusionresistance diaphragm ke filimi ea polasetiki.Lefapheng la lihlahisoa tsa polasetiki, hangata re bua ka lihlahisoa tsa polasetiki tse bataletseng tse nang le botenya bo ka tlase ho 0.2 mm e le lifilimi tsa polasetiki, tse nang le botenya pakeng tsa 0.2 le 0.7 mm e le maqephe a polasetiki le tse nang le botenya bo fetang 0.7 mm e le lipoleiti.Multilayer co-extrusion resistance diaphragm e tla ba le ts'ebetso e itseng ea thibelo ea khase.Tšitiso mona e bua ka bokhoni ba ho sireletsa lihlahisoa tsa polasetiki (lijana, lifilimi) khahlanong le likhase tse nyenyane tsa molek'hule le monko o monate.Hangata re sebelisa matla a khase ho lekanya ho kenella ha lihlahisoa tsa polasetiki.PE, PP le li-plastiki tse ling tse akaretsang li na le litekanyetso tse kholo tsa khase, ke hore, ho kenella ha khase ho fokola, ha PA, PVDC, EVOH le lisebelisoa tse ling tsa resin li na le boleng bo tlaase haholo ba khase ho feta polasetiki e akaretsang, 'me ho kenella ha khase ho molemo.Ka hona, hangata re bitsafilimi ea multilayer coextrusione nang le bonyane thepa e le 'ngoe ea resin ea PA, PVDC le EVOH joalo ka multilayer coextrusion resistance diaphragm.PE, PA, TIE, EVOH le li-resin tse ling li ka sebelisoa bakeng sa ho paka lihlahisoa tsa lebese, jeme, lihlahisoa tsa nama, joalo-joalo.

Lifilimi tse kopaneng tsa Multilayerboholo ba amohela sebopeho se lekanang sa ABCBA5, se nang le PA kapa EVOH joalo ka mokoallo oa mokoallo le polyethylene joalo ka lera la tiiso ea mocheso.Resin ea sekhomaretsi e sebelisetsoa ho arola lera le sa amaneng la mokoallo le lera la tiiso ea mocheso.PA kapa EVOH e na le kutloelo-bohloko haholo ho mongobo, e sirelelitsoeng ke lera la polyethylene, mme ts'ebetso ea eona e ntle ea thibelo ea oksijene e ntlafalitsoe ka botlalo.Ka kakaretso, sebopeho safilimi ea multilayer co-extrudedho itšetlehile ka litlhoko tse sebetsang tsa filimi.Motheong oa ho fihlela litlhoko tsa ts'ebetso, motsoako oa li-polymer tse fapaneng o ka fihlela litlhoko tsa ts'ebetso ea lisebelisoa tsa ho paka joalo ka mokoallo, ho tiisa mocheso, matla a 'mele, ho phunya mocheso, ho ikamahanya le maemo a tikoloho, litšobotsi tsa ts'ebetso ea bobeli le ho atolosoa ha polokelo le bophelo ba sethala.Ho ea ka pono ea litlhoko tsa ts'ebetso, ho kopana ha li-polymers tse hlano ho lekane.Leha ho le joalo,filimi e kopantsoeng e kopantsoengle tse supileng, robong, leshome le motso o mong kapa ho feta le dikarolo e 'nile ea sebelisoa' marakeng hore etsa hore e le mokhoa le ho ntshetsa pele ka potlako.Sebopeho sa sebopeho sa filimi e kopantsoeng se hlokahalang butle-butle ho finyella boemo bo botle ba ho kopanya mosebetsi, theknoloji, litšenyehelo, tšireletso ea tikoloho, polokeho le ts'ebetso ea bobeli.

1. Papiso ea litšenyehelo

Ho sebelisa li-polymers tse theko e tlaase holimo ho e-na le li-polymer tse theko e boima ho ka fokotsa litšenyehelo tsa lihlahisoa 'me ho na le ts'ebetso ea ho tiisa mocheso le ho hanyetsa mongobo o phahameng oa li-polymer tsa ionic chain.Bakeng sa lisebelisoa tse nang le mokoallo o tšoanang le mocheso-seal-bokhoni ba 7-layer co-extrusion blown filimi e na le chelete e ngata ho feta filimi ea 5-layer.

2. Tšitiso

Ho sebelisa li-polymer tse peli tse fapaneng ho e-na le polymer e le 'ngoe holim'a mokoallo oa mokoallo ho ka ntlafatsa thepa ea eona ea thibelo haholo.Ka mohlala, motsoako oa EVOH layer le thepa e tloaelehileng ea nylon e ke ke ea boloka ho kenella ha PA feela, empa hape e eketsa matla a EVOH le ho ntlafatsa ho hanyetsa ha EVOH hobane lera la EVOH le kenngoa pakeng tsa likarolo tse peli tsa PA amine, ho etsa hore filimi e nang le mokoallo o phahameng, ha filimi ea co-extrusion ea lihlopha tse hlano e ke ke ea finyelloa.Theko e ntseng e eketseha ea ho eketsa EVOH e ka ekeletsoa ho kakaretso ea tšebeliso ea mohaho.Sekhahla sa phetisetso ea oksijene ea filimi e kopantsoeng ea likarolo tse hlano e nang le 20% PA sebopeho ke li-unit tsa 3.5, empa tlas'a maemo a tšoanang, tekanyo ea phetisetso ea EVOH e kenyellelitsoeng filiming ea lihlopha tse supileng ke li-unit tsa 0.13.

3. Crack resistance

Thepa ea lifilimi tse kopantsoeng tsa PA tse nang le likarolo tse ngata li ka ntlafatsoa.Ka mohlala, tšebeliso ea lera e eketsehileng ea sekhomaretsi e ka ntlafatsa ts'ebetso ea mokoallo oa filimi ka ho eketsa phello ea mokoallo oa mouoane oa filimi.Molemo o mong o fumanoeng ka nako e le 'ngoe ke hore o ka etsa hore filimi e be bonolo haholoanyane, e ikutloe e le monate' me e be le khanyetso e ntle ea crack.

Ka tsoelo-pele e tsoelang pele ea theknoloji ea polymer synthesis, li-polymer tse ncha tse nang le thepa e ikhethang ea 'mele le ea mochini li ka sebelisoa haholo ho fihlela litlhoko tsa ho paka.Mosebetsi le sebopeho safilimi ea multilayer co-extruded composite substratee tla ba le phetoho e kholoanyane le moruo.Ka ts'ebeliso le ntlafatso ea lisebelisoa tsa ho bopa le theknoloji, e kopantsoeng le moralo o ikhethileng le o sebetsang oa sebopeho se kopaneng, bahlahisi ba lifilimi ba tla ba le karolo ea phetoho molemong oa ho lelekisa le ho nahana ka mehopolo ea mefuta e fapaneng ea mesebetsi ea ho paka, ho fana ka mabaka a sebopeho sa liphutheloana, le ho eketsa melemo ea ho paka.

Nako ea poso: Apr-17-2023